According to a recent analysis by MIT researchers, if the majority of light-duty vehicles in the United States ran on higher-octane gasoline, the automotive industry as a whole would reduce its carbon dioxide emissions by 35 million tons per year, saving up to $6 billion in fuel costs.

Market analysis also shows that from a global view, the octane number of commercial gasoline is at or below the lower limit of the acceptable range in many countries.

Since wider use of premium gas could save fuel, money and is helpful to the environment, refineries have tried to use new processes and catalysts to improve gasoline octane number, but still have trouble in fully meeting the consumers’ requirements. An additive solution is a much better option instead and has drawn high attention and appreciation from the majority of customers.

The first widely used octane additive was TEL(tetraethyl lead). Since TEL is highly toxic and harmful to the human body and the environment, it has been phased out in gasoline by the United States Environmental Protection Agency (EPA) in 1973. However, TEL has been, and still is, used in certain countries.

As a replacement to TEL, a less-toxic substitute, MMT (Methylcyclopentadienyl manganese tricarbonyl was used since1974. MMT has been so controversial that many oil companies voluntarily terminate the use of MMT, so do some of the automobile manufacturers. It has been banned in certain countries due to its neurotoxicity.

MTBE(methyl tert-butyl ether), has been used as an anti-knocking agent in gasoline at low levels since 1979. However, due to its contamination of groundwater and soil, in 2000 the U.S. EPA drafted plans to phase out the use of MTBE nationwide over four years. As of 2016, hundreds of lawsuits are still pending regarding MTBE contamination of public and private drinking water supplies.

There are several other alternative additives, including DMC (dimethyl carbonate), sec-Butyl acetate, Aniline, N-Methylaniline. However, these additives have not been widely applied since they all have their own drawbacks of too expensive, very toxic, incompatible with engine and fuel system materials, etc. Some of these compounds also cause serious environmental or healthy concerns and are banned in many countries.

Cestoil has decades of professional experience in supplying fuel additives. With our customers’ requirements in mind and years of research findings, Cestoil has developed a new generation of organic octane booster and obtained a major technological breakthrough. Our patented products have the advantages of high performance, cost-effective, ashless, and environmentally friendly. It is fully compatible with other fuel additives and the materials composing engine and fuel system.

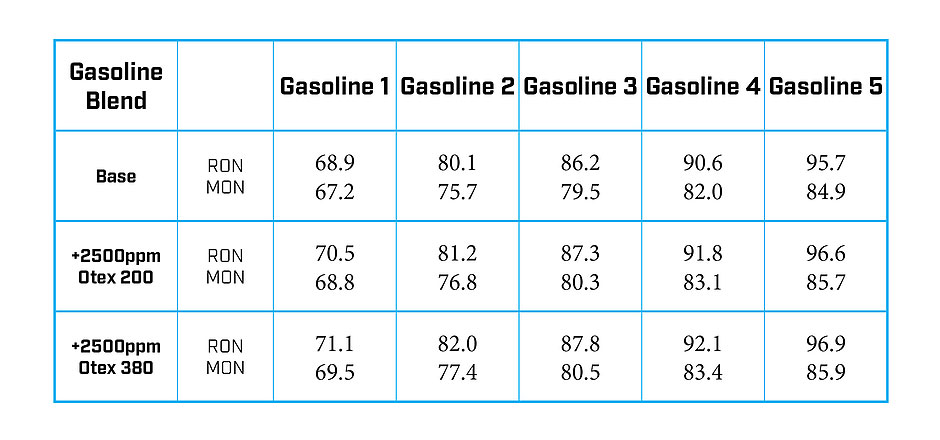

It is shown that both RON and MON could be enhanced obviously. Similar to other octane boosters, Otex makes a better response to lower RON gasoline. At a surprisingly low dosage of 2500ppm, it can increase the RON up to 1.5 points.

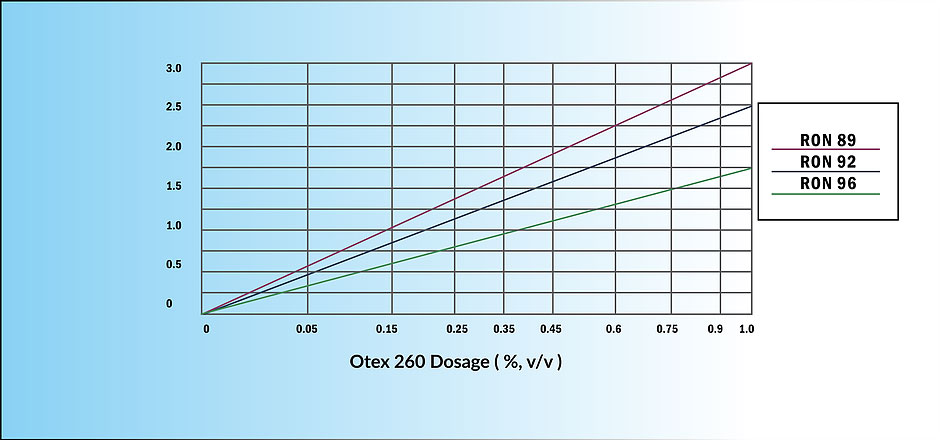

The above data shows the typical performance of Otex260 on various gasoline. Note: Otex260 is our low pour point version of Otex200.

Our recommended dosage for Otex octane boosters ranges from 1000 to 2500ppm.

Cestoil’s engineers will provide an optimal dosage after evaluating the gasoline status and the user’s needs.

Otex can be added in either concentrated form or in a stock solution using a metering pump, injection system or batch addition.

Otex is compatible with other common fuel additives and with engine and fuel system materials.

Please follow the safety precaution instruction for the general chemical additives to handle the product.